$-*."5&$)"/(&"%"15"5*0/'034."--)0-%&3

'"3.&34*/4065)"'3*$"

70-6.&1"35"/*.1-&.&/5"5*0/"/%4611035(6*%&

-0$"-(3061#"4&%"$$&44508"5&3'03)064&)0-%

'00%130%6$5*0/

77

Climate Change Adaptation for

Smallholder Farmers in

South Africa

Volume 2 Part 3: An implementation and

support guide: Local, group-based access to

water for household food production

E Kruger, MC Dlamini, T Mathebula, P Ngcobo, BT Maimela & L Sisitka

Report to the

Water Research Commission

by

Mahlathini Development Foundation

WRC Report No. TT 841/4/20

February 2021

ii

Obtainable from

Water Research Commission

Private Bag X03

Gezina, 0031

orders@wrc.org.za or download from www.wrc.org.za or www.mahlathini.org

The publication of this report emanates from a project entitled Collaborative knowledge creation and

mediation strategies for the dissemination of Water and Soil Conservation practices and Climate Smart

Agriculture in smallholder farming systems. (WRC Project No.K5/2719/4)

This report forms part of a series of 9 reports. The reports are:

Volume 1: Climate Change Adaptation for smallholder farmers in South Africa. An implementation

and decision support guide. Summary report. (WRC Report No. TT 841/1/20)

Volume 2 Part 1: Community Climate Change Adaptation facilitation: A manual for facilitation of

Climate Resilient Agriculture for smallholder farmers. (WRC Report No. TT 841/2/20)

Volume 2 Part 2: Climate Resilient Agriculture. An implementation and support guide: Intensive

homestead food production practices. (WRC Report No. TT 841/3/20)

Volume 2 Part 3: Climate Resilient Agriculture. An implementation and support guide: Local, group-

based access to water for household food production. (WRC Report No. TT 841/4/20)

Volume 2 Part 4: Climate Resilient Agriculture. An implementation and support guide: Field cropping

and livestock integration practices. (WRC Report No. TT 841/5/20)

Volume 2 Part 5: Climate Resilient Agriculture learning materials for smallholder farmers in English.

(WRC Report No. TT 841/6/20)

Volume 2 Part 6: Climate Resilient Agriculture learning materials for smallholder farmers in isiXhosa.

(WRC Report No. TT 841/7/20)

Volume 2 Part 7: Climate Resilient Agriculture learning materials for smallholder farmers in isiZulu.

(WRC Report No. TT 841/8/20)

Volume 2 Part 8: Climate Resilient Agriculture learning materials for smallholder farmers in Sepedi.

(WRC Report No. TT 841/9/20)

DISCLAIMER

This report has been reviewed by the Water Research Commission (WRC) and approved for

publication. Approval does not signify that the contents necessarily reflect the views and policies of

the WRC, nor does mention of trade names or commercial productsconstitute endorsement or

recommendation for use.

ISBN 978-0-6392-0230-3

Printed in the Republic of South Africa

© WATER RESEARCH COMMISSION

iii

ACKNOWLEDGEMENTS

The following individuals and organisations deserve acknowledgement for their invaluable

contributions and support to this project:

Chris Stimie (Rural Integrated Engineering – RIEng)

Dr Brigid Letty and Jon McCosh (Institute of Natural Resources – INR)

Nqe Dlamini (StratAct)

Catherine van den Hoof (Researcher)

Dr Sharon Pollard, Ancois de Villiers, Bigboy Mkabela and Derick du Toit (Association for Water and

Rural Development)

Hendrik Smith (GrainSA)

Marna de Lange (Socio-Technical Interfacing)

Matthew Evans (Web developer)

MDF interns and students: Khethiwe Mthethwa, Samukhelisiwe Mkhize, Sylvester Selala, Palesa

Motaung and Sanelise Tafa

MDF board members: Timothy Houghton and Desiree Manicom

PROJECT FUNDED BY

REFERENCE GROUP MEMBERS

Prof S Mpandeli Water Research Commission

Dr S Hlophe-Ginindza Water Research Commission

Dr L NhamoWater Research Commission

Dr O CrespoUniversity of Cape Town

Dr A Manson KZN Department of Agriculture and Rural Development

Prof S WalkerAgricultural Research Council

Prof CJ RautenbachPreviously of WeatherSA

COLLABORATING ORGANISATIONS

https://inr.org.zahttps://award.org.za/

https://amanziforfood.co.za/

https://foodtunnel.co.za/http://www.rieng.co.za/

iv

ABBREVIATIONS AND ACRONYMS

CA Conservation Agriculture

CC Climate change

CCA Climate change adaptation

CRA Climate resilient agriculture

EC Eastern Cape

KZN KwaZulu-Natal

MDF Mahlathini Development Foundation

SOC Soil organic carbon

SOM Soil organic matter

TLB Tractor Loader Backhoe

v

TABLE OF CONTENTS

ACKNOWLEDGEMENTS .......................................................................................................................iii

PROJECT FUNDED BY..........................................................................................................................iii

REFERENCE GROUP MEMBERS ........................................................................................................iii

COLLABORATING ORGANISATIONS ..................................................................................................iii

ABBREVIATIONS AND ACRONYMS .................................................................................................... iv

TABLE OF CONTENTS .......................................................................................................................... v

1BACKGROUND AND INTRODUCTION .......................................................................................... 1

1.1IMPROVING WATER ACCESS FOR CLIMATE-RESILIENT INTENSIVE HOMESTEAD

FOOD PRODUCTION PRACTICES ....................................................................................... 1

THE CURRENT SITUATION .............................................................................................. 1

GROUP-BASED ACCESS TO WATER SOURCES........................................................... 1

1.2SPRING PROTECTION AND RETICULATION IN EZIBOMVINI, BERGVILLE (KZN) .......... 2

1.2.1 PROGRESS IN JULY 2019 ................................................................................................ 2

1.2.2 PHASE 1: PROTECTION OF THE SPRING AND LAYING OF THE MAIN PIPE TO THE

HEADER TANK...................................................................................................................3

1.2.3 INITIAL COMMENTS AFTER INSTALLATION...................................................................5

1.2.4 PHASE 2: LAYING PIPES AND INSTALLING DRUMS FOR EACH PARTICIPATING

HOUSEHOLD......................................................................................................................6

1.2.5 THE HEADER TANK AND RETICULATION TO THE HOUSEHOLDS...............................7

1.2.6 CONCLUSION.....................................................................................................................8

1.3BOREHOLE INSTALLATION AND WATER RETICULATION IN SEDAWA AND TURKEY

(LIMPOPO) .............................................................................................................................. 9

INTRODUCTION ............................................................................................................... 10

POSSIBLE LOCATIONS AND BOREHOLE SURVEY ..................................................... 10

CHOOSING LOCATION FOR BOREHOLE DRILLING BY PARTICIPANTS................... 10

DESIGNING AND MAPPING THE MAINLINE PIPELINES .............................................. 11

DECISION-MAKING WITH MDF AND THE PARTICIPANTS.......................................... 12

CONTINUING WITH INSTALLATION OF PUMPS AND HEADER TANKS ..................... 13

PLANNING THE DIGGING OF THE MAIN PIPELINE TRENCHES ................................ 14

LAYING THE PIPES FROM THE HEADER TANKS TO THE HOMESTEADS................ 16

CONNECTION OF PIPES IN TURKEY............................................................................ 17

CONNECTION OF PIPES IN SEDAWA ........................................................................... 17

1

1 BACKGROUND AND INTRODUCTION

1.1 IMPROVING WATER ACCESS FOR CLIMATE-RESILIENT INTENSIVE HOMESTEAD FOOD PRODUCTION

PRACTICES

The current situation

Homestead food production is an important aspect of the smallholder farming system. These systems

are small (0,01-0,5 ha; or 100-5 000 m2) plots adjacent to homesteads where participants plant a range

of crops and fruit trees, with or without access to water for irrigation. The homesteads also host small

livestock such as poultry and, in some cases, goats and cattle. A limited number of people also keep

pigs. These plots are usually fenced. The large majority of smallholders plant for household

consumption and sale of surplus.

Production is constrained by infertile and badly structured soils. Often, the smallholders live in areas

where soils are not ideal for cropping. This situation is worsened by repeated shallow tillage (with hand

hoes and/or tractors), without the addition of nutrients or organic matter, often over many years. The

results are very low fertility soils, with many structural problems such as capping and compaction. This

is now exacerbated by climate change, with alternating hot and dry conditions and heavy downpours

adding extensive erosion of topsoil to the list of woes. Productivity is generally extremely low.

In addition, access to water for irrigation is an enormous obstacle for most smallholders, who battle to

have enough just for household use.

Water management in an intensive food production system consists of:

xReduction in run-off and water erosion; mostly through measures such as diversion ditches

infiltration basins, contours, stone bunds, check dams and the like.

xImproved water-holding capacity; mostly through increased organic matter in the soil,

mulching and microclimate management (such as improved shade and reduced wind).

xImproved water-use efficiency; mostly through irrigation management, drip irrigation and

greywater management.

xImproved access to water; mostly through small dams, spring protection and drilling of

boreholes.

Improved access to water can take several forms and interventions are generally conceived as large

infrastructure projects implemented through government and municipal processes. In this report, we

focus on increasing local level access through processes that groups of individuals can undertake within

their communities.

Group-based access to water sources

Water is considered a communal resource and as such water projects need to accommodate all

community members. For the large majority of rural settlements, water access is about household water

needs and it is this aspect that government services focus on.

It is possible to conceptualise water provision for agriculture at a village level, where an interest group

of smallholders undertake to manage and use a specific water resource, such as a spring, or a borehole,

with consent from the local authorities and Water Service Authority representatives. We do not include

rivers and perennial streams in this activity, as water offtake and management from these sources is

socially, politically and environmentally a lot more complicated and does require the whole community

to be involved.

Group-based water management options have the advantage that participants can “own” their scheme

and thus have a lot more control over their water access. It also has the advantage that the group itself

designs, implements, maintains and manages access for the members. The members are responsible

for water use and management and are accountable to each other.

2

In this document two case studies are provided as examples of how this can be done:

xSpring protection and water reticulation for nine households in Ezibomvini, Bergville, KZN.

xBorehole installation and water reticulation for two village-based groups of 20 members

each in Sedawa and Turkey, Limpopo.

1.2 SPRING PROTECTION AND RETICULATION IN EZIBOMVINI,BERGVILLE (KZN)

The Climate Resilient Agriculture learning group in Ezibomvini consists of around 36 members. They

have implemented Conservation Agriculture practices for their field cropping and intensive household

food production for vegetable production. Access to water in the village is extremely limited, with one

or two municipal boreholes with hand pumps providing household water. Not unusually, access to this

water is inconsistent, as pumps break and are not fixed, or the boreholes become unreliable and the

situation is not rectified. Access to irrigation for farming is non-existent. Most community members also

get water from local springs, which are unprotected and shared with the livestock in the area.

There are informal arrangements in the community about access to these springs, and almost everyone

in the immediate surroundings has access.

The learning group, under the proactive leadership of their local facilitator, Phumelele Hlongwane began

discussing the possibility of protecting a few of these springs and piping water to their households to

facilitate their vegetable production efforts, as the spring is far away, requiring about a 1 km walk with

buckets. This has severely limited their production ability.

The group presented their concept to MDF and requested assistance with planning and implementation.

Each member who wanted to be involved gave a financial donation of R1 000 and agreed to provide

the labour for digging trenches and installing pipes and tanks.

This process was initiated in August 2018 and was suggested by the Ezibomvini learning group as a

way to provide both household water and agricultural water for the homestead gardens.

A survey of the local springs and potential options was conducted with assistance from an agricultural

engineer. A process was initiated for the group to come together and collect monies, which would be

matched by a grant from MDF, to provide for a small fund to protect and reticulate one of the springs,

with a simple gravity fed system to participants’ homesteads.

The participants undertook to provide R1 000 per household. This process took some time and by

September 2019 an amount of R8 000 had been put together. MDF then decided to continue with the

process. Phumelele Hlongwane, the local facilitator and the main driver of this process, promoted the

initiative tirelessly throughout this period. She initially put down R7 000 and also offered her 2 200 litre

JoJo tank as the header tank. She has subsequently been paid back most of this money.

Nine participants paid and comprised the water committee: Lungile Sithole, Cabangani Hlongwane,

Phumelele Hlongwane, Phumelele Gumede, Goodman Dlamini, Landiwe Dlamini, Hlengiwe Nkabinde,

Mantombi Mabizela and Devu Dlmaini/Velephi Zimba.

1.2.1 Progress in July 2019

Conflict emerged early and needed to be resolved. In one homestead there were two participants and

an agreement was reached that both needed to pay. Those who had paid but decided to withdraw had

their monies returned to them. Another participant, Landiwe Dlamini, requested that water be provided

at her new homestead site (across the road and much further downhill than the rest of the group). It

was reiterated that water provision was limited and that it was for homesteads and gardens only. For a

time, people believed that after elections the municipality would deliver the promised centralised water

provision to the area. This did not materialise. Petty squabbles around turf and trust also delayed

implementation. Actual work on the process started in September 2019

3

1.2.2 Phase 1: Protection of the spring and laying of the main pipe to the header tank

The spring is typical of the area, in that the eye is situated in a bank quite close to the streambed.

Local participants have dug out a small catchment dam for the spring, from which people collect water

and from which cattle also drink.

Figure 1: Left: The

spring’s catchment pond

with evidence of use by

cattle and people. Right:

The catchment pond dug

out to make a bigger

pond and small dam wall.

It was thus important that this

part of the spring could still be

shared by the community, as

the water group did not directly

“own” the spring.

Consequently, the design included an offtake from the spring consisting of a slotted pipe buried in a

trench filled with gravel and stones below the main catchment dam for the spring. This trench could be

completely closed up and covered with soil to avoid any damage and tampering. And it left a source of

water from which those not involved in the project could collect their water.

Figure 2: Left: The capped end of the 1 m length (50 mm diameter) slotted pipe that provides for the

below-ground offtake of water from the spring. Right: The fittings linking this slotted pipe to the main

pipe (50 mm HDPE) (from Chris Stimie – RIEng).

4

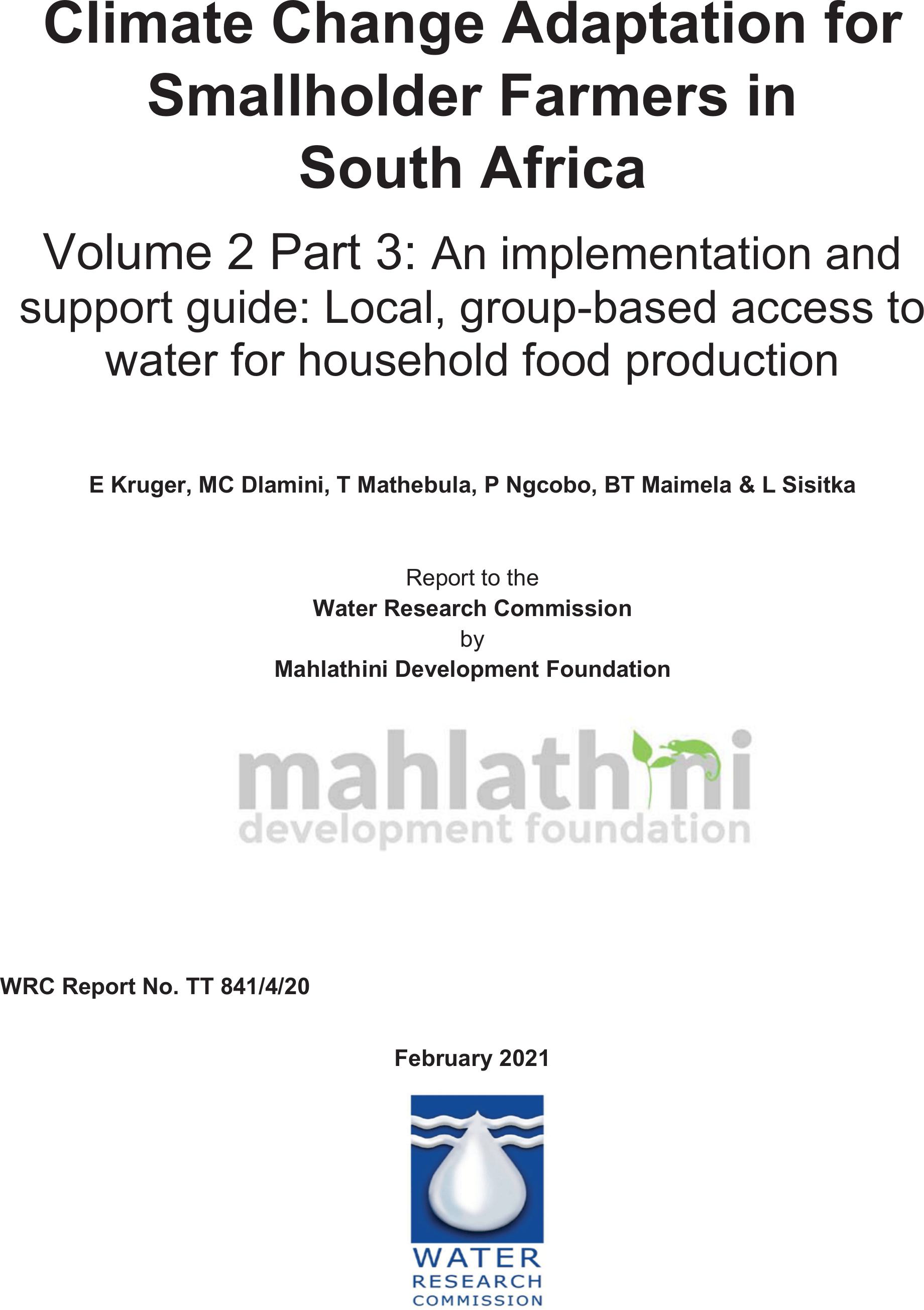

Figure 3: Photographs showing the process of installing the slotted pipe for collection of water from the

spring

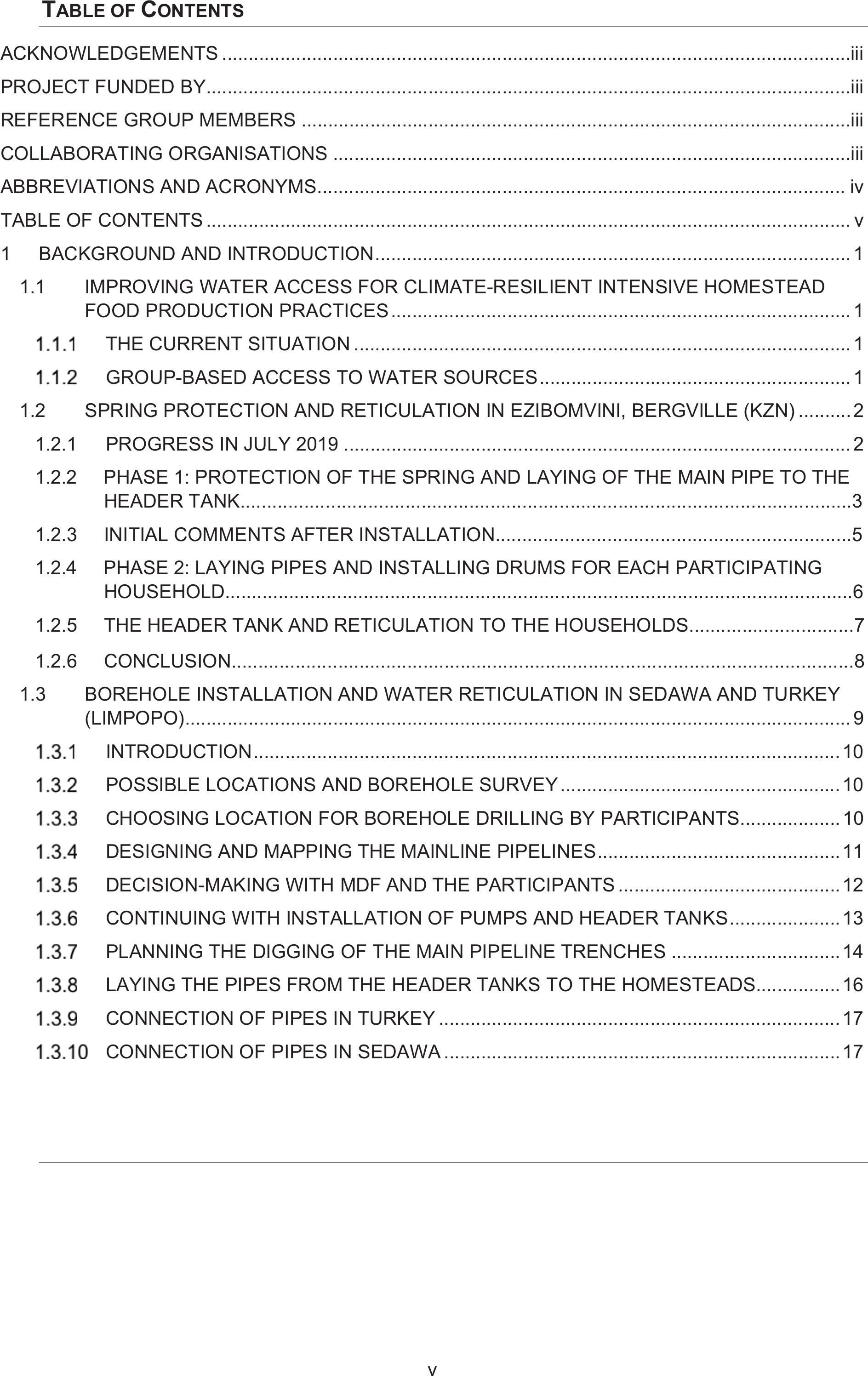

The spring is situated in the veld above the village and thus allows for a gravity-fed system. Because

this is a low-pressure system and the main pipe to the header tanks is around 350 m long, it is important

that the ditch for this pipe be placed on an even slope. If this is not done, the water will not flow – which

the group found out the hard way when they initially just dug a ditch and tried to lead water from the

spring.

Following the contours of the land, with the pipe rising and falling accordingly, could lead to air bubbles

that stop the flow of the water. These airlocks are extremely difficult to remove without having release

valves at the correct points in the pipe. An even gradient for the pipe removes this problem.

Figure 4: Left: measuring the gradient for the main pipeline using a dumpy level. Right: Adjusting the

line for the pipe to avoid some of the larger dongas and rough terrain, while keeping it on an even

gradient.

Starting on the trench for the

slotted pipe, below the spring

and pond

Deepening and widening this

trench to 50 cm x 50 cm x 1,2 m

The trench with slotted pipe

installed in a bed of gravel,

covered by shade cloth and

rocks with a small furrow

leading water from the spring

to this trench

The trench damaged by

livestock before it could be

properly covered and closed.

5

The ditches were dug around 30 cm wide and 40 cm deep – evenly throughout the length of the pipe.

These ditches were dug by the learning group participants as their contribution in kind to the process.

A header tank with a ball valve (in this case a 2 200 L tank with a drinking-trough ball valve) is placed,

ideally at the group’s highest homestead. For this group, however, it was placed at Phumelele

Hlongwane’s homestead as she was the leader of the group and prepared to do the daily opening and

closing of taps to provide water to the rest of the learning group members.

Figure 5: Left to right: Group members digging the ditch from the spring to the header tank. The header

tank at Phumelele Hlongwane’s homestead – which was not installed on a level platform and has

subsequently been corrected. Initial rough layout drawing of the flow of the water to participants’

homesteads.

Once it was ascertained that the water actually flowed into the header tank, the time taken to fill it was

carefully recorded over a few days. In this way, the water flow and overall capacity of the spring was

determined. This was then used to work out the daily water allocation for each of the nine participants.

As at November 2019, due to dry conditions in the area and low flow of the spring (2 200 L in seven

hours, thus ~300 L/hr), participants were allocated 200 L drums with ball valves. These can be filled

twice a day – once in the morning and once in the late afternoon.

1.2.3 Initial comments after installation

Summary of observations:

xWater was being decanted from the 2 200 L header tank straight into participants’ 200 L drums

before the tank was full.

xThe water was somewhat muddy due to the damage caused in the offtake trench by cattle.

xThe water was running very slowly, which was disappointing for the participants who were

hoping for more water.

xParticipants suggested making the small pond/dam bigger. It was explained that this would not

increase the flowrate of the spring.

xOne participant also suggested closing up the whole spring to get more water. It was stressed

that the spring was communal and that removing access entirely was likely to cause conflict in

the community. Participants also mentioned an old community belief that when you completely

close a spring, then the “water owner/spirit” will it dry up and move it to another place.

6

The facilitation team stressed by that this was an experiment in working together and taking

responsibility for management of a local resource. There was no precedent. This meant that they would

need very clear agreements and trust that everyone would to stick to the rules that they made. If only

one person reneged, or tried to take more water than their allocation, or left their tap open, it would

mean that none of the other participants would get water. This would quickly escalate into major conflict

among the participants. Thus, was important to commit entirely to the process at the beginning.

The following rules were subsequently agreed to:

xThe header tank needs to be left to fill up. Then the tap will be opened and the 200 L drums for

each household will fill up.

xOnce the top household’s 200 L drum is full, the tap for the header tank is again closed – so

that it can fill up again.

xNo-one can use water while their drum or tank is filling up. You need to wait until it is full, and

the main tap is closed.

xEach person can receive 2 x 200 L in one day – so, for example, at 8 am in the morning and

again eight hours later at 4 pm.

xThe header tank will be left to fill up and remain full overnight, so as not to draw too much water

from the spring.

xPhumelele Hlongwane will have access to 3 x 200 L drums – more water than the other

participants. (This agreement was made because she is responsible for checking the header

tank and opening and closing the main tap twice a day. She also provided a greater initial

financial contribution).

1.2.4 Phase 2: Laying pipes and installing drums for each participating household

Thereafter, a discussion was held about where the ditches would go for the pipes to peoples’

households. It was agreed that the main feeder pipe would be dug along the small road to Phumelele’s

house, that people would take their pipes off this line, and that the pipes would go through a few of the

participants’ fields. It was agreed that Landiwe’s main homestead, but not the second, could be included

in the system, and that no more participants would be included – those who had not yet paid would be

removed from the list.

GPS coordinates were taken for each participating household using “Maveric” (a free cell phone App)

and then plotted on a map using Google Earth. From this map, heights and distances could be

determined and thereby who could receive gravity-fed water from the header tank and how much piping

would be required.

7

Figure 6: Creating a Google Earth map from GPS coordinates using cell phones is not very accurate,

so a correction was made. The blue line indicates the main feeder pipe to participants’ homesteads

running along the small road to Phumelele Hlongwane’s homestead.

1.2.5 The header tank and reticulation to the households

The learning group constructed a level plinth for the header tank after it

collapsed in a storm due to the initial, less secure arrangement of cement

bricks and a pallet. This was an important lesson for the group where an

attempt to save money and effort led to this unfortunate event. The group

shouldered the setback well and collaborated to construct the more

secure plinth.

They then dug the ditches for the pipes leading to their households

according to the discussion and map provided for them and with

assistance from MDF field staff. Each household procured the 200 L

drum required. This was done within a week, after which the agricultural

engineer assisted in laying the procured piping and installing the

necessary connections and float valves in the drums.

Figure 7: Plinth for the 2 200 L header tank

8

Figure 8: Left to right: Laying the piping along the edges of the fields. Pipe branches towards the

different homesteads. Fitting the inlet pipes to the 200 L drums. Installation of a float valve in each drum.

The group also agreed not to have taps installed in the drums, but to take water from the top of the

drums. The system began operating after a few false starts when participants tried to take water before

the drums were full and the tap at the header tank had been shut off. Participants eventually came to

understand that none of their drums would fill up unless everyone waited until they were all full and the

main tap had been closed. This is a requirement due to the low flow of the spring and the gravity-feed

system.

1.2.6 In conclusion

Five months after installation, the project was still functioning well and all nine households were

receiving their allocations of water. Some maintenance had been done to leaking connections and float

valves. All members were very happy with easier access to water for household and gardening

purposes and felt that this scheme would really come into its own in the winter of 2020. Phumelele

Hlongwane found that managing the header tank was not too problematic or time-consuming and was

very relieved that the process was running so well.

Figure 9: Left: The Gumede family’s drum with water five months into the scheme’s management.

Centre: Mr Nkabinde’s drum. Right: Phumelele’s three drums.

This has been an extremely valuable process for building social agency in the learning group as well

as for systemic and systematic learning for all the group members. They had to grapple with both the

9

understanding of the technical aspects as well as the social process that they had to put in place and

adhere to.

The whole group was involved throughout, and learning took place through discussions, provision of

information, working with the mapping and layout aspects, and practical work. A lot of the learning

happened through trial and error, as participants started changing their perceptions and understanding.

Some of the technical aspects that participants needed to experience before fully appreciating them

were:

xThat increasing the size of the small dam for the spring would not increase the amount of

available water – which was primarily dependent on the strength of the spring.

xThat the underground water flow into the slotted pipe was just as strong as or stronger than

water flowing in a ditch above the ground.

xThat the main pipe taking water from the spring to the header tank needed to be on an even

gradient even though the header tank was situated well below the level of the spring. The initial

ditch that was dug by participants did not adhere to this principle and water did not reach the

header tank. This had to do with the broken terrain, the formation of air bubbles in the pipes

and the weak flow of the spring itself.

xThat households above the header tank were unable to receive water from this gravity-fed

system and that estimating the level of the household compared to the tank did not work well –

this is something that needs to be measured, and was done with GPS coordinates and Google

Earth maps in a participatory fashion.

xThat the header tank must be on a secure and level plinth due to the weight of the water in the

tank.

xThat a gravity-fed system fills up the drums from the bottom of the slope first.

xThat the filling of the household drums was dependent on everyone not using water until all the

drums were full and the main tap on the header tank had been closed.

In terms of the social aspects, participants initially believed it would be easy for them to manage the

water use, but they very quickly realised that it was very important to have upfront and strict rules to

ensure that everyone received the same allocation of water. This was a deeply empowering process

for learning group participants.

1.3 BOREHOLE INSTALLATION AND WATER RETICULATION IN SEDAWA AND TURKEY (LIMPOPO)

Access to water for household purposes and small-garden household food production has become the

most pressing problem in the Lower Olifants region of Limpopo. In some areas there are no water

services at all and people still rely on local springs that they share with their livestock. In other areas,

the few boreholes/wells that have been provided by local governments are running dry, have broken

down and are inadequate to provide for everyone in the community. In these villages, women now have

to buy water and must survive off around 200 L of water per week for their entire household. Even under

these circumstances the women are still trying to cooperate to produce small quantities of food.

In two villages (Sedawa and Turkey in the Mametja area of Limpopo) women and men formed water

committees to cooperate to source water for their households and gardens. They received the

necessary permissions from their traditional authorities, but undertook to do this work independently of

government officials, given the perceived high levels of corruption in local government circles and local

government’s lack of commitment to support poor rural people’s agricultural activities The water

committees collected small amounts of money (R500/household) and developed plans for drilling

wells/boreholes and sharing the water.

Financial assistance was found for these groups as the infrastructural costs of drilling boreholes and

reticulating gravity-fed systems for so many participants (20 per group) was unaffordable for them. As

10

was the case in KZN, participants volunteered their labour for digging trenches and laying pipes and

agreed to arrange for their own homestead storage containers.

Introduction

Initially, meetings were held with the two water committees representing four learning groups across

four villages to discuss how the process could be undertaken and to work through some of the logistical

and financial details. Participants were given the task of looking for possible locations that had good

groundwater retention potential to be

surveyed and to look for drilling

companies that had worked in their

villages, and whom they trusted. The

groups also finalised participants to be

involved and their financial and labour

contributions to the project.

Figure 10: One of the water

committee meetings held in

Turkey in November 2019 to

prepare for the borehole project

Possible locations and borehole survey

Participants from each village chose two to three possible locations to be surveyed as a starting point.

Raymond Vonk from Georay geophysical services and his assistant undertook the surveys using a

process that incorporates both vertical electrical sounding and horizontal profiling activities. These tools

determine the depth and thickness of various subsurface layers and their relative water-yield capacity.

They started working at Turkey 1 with the water committee members and MDF fieldworker, Betty

Maimela. Raymond moved along the most plausible lines from the positions suggested and the best

option for drilling was calculated from there. Private property such as orchards and existing unutilised

boreholes as well as other obstacles were considered. He also surveyed three suggested locations at

Sedawa.

Figure11: Left: View of rock and pebble formations typical of an area where subsurface water is flowing.

Right: Raymond surveying at Turkey 1.

Choosing location for borehole drilling by participants

The process of choosing the right location was difficult. From the options provided, participants had to

consider distances between the borehole and their homesteads, options for where the header tank

would be and where the mainline pipes would go. Some conflict arose due to a lack of trust and some

11

participants initially refused to accept and discuss these challenges objectively. It took a few meetings

and a lot of discussion to make these decisions, after which Betty used

the cell phone appMaverick to survey the GPS coordinates of each

household. This was in order to map out (using Google Earth) the

participants’ respective distances and heights to design the best

possible system within the given constraints of topography and budget.

The maps assisted in outlining the quantity and type of pipe to be used

and clarified that some participants were too distant or elevated to be

serviced. Further negotiation was required, which saw the removal of

piping to irrigated fields – these were all over one kilometre away and

participants did not see themselves being able to afford and install their

own piping. For those few households that fell above the header tank,

arrangements were made to provide tanks for them at a household

nearby.

The drilling company that participants preferred was not immediately

available and eventually everyone agreed on the agricultural engineer’s

recommendation – Afrisolutions from Tzaneen – who were already

working in the area and had experience installing community-based

infrastructure. There was a lot of debate about the reliability of drilling

companies.

Figure 12 (Right): Core samples taken during the drilling

process. These pictures were sent to Mr Vonk to determine whether drilling should continue

or stop, based on the structure and consistency of these samples.

Figure13: Left: The drilling machine. Right: Water starting to flow during the drilling process.

Only two of the four proposed boreholes drilled were successful, yielding around 14 000 L/hr (Sedawa

1) and 500 L/hr (Turkey 2) respectively.

Designing and mapping the mainline pipelines

The agricultural engineer worked closely with Betty to finetune and finalise the maps. These were

discussed and negotiated with the water committee groups repeatedly until everyone agreed. The maps

also indicated the size of pipes and the different connectors needed. Pipe sizes differed to ensure even

pressure within the system and a reasonably even supply of water to all households.

12

Figure14: Map of a section of the Sedawa pipeline outlining the different pipe sizes in different colours

Figure15: Map of a section of the Turkey 2 pipeline with the different pipe sizes indicated in different

colours

Decision-making with MDF and the participants

Once the boreholes were drilled, a number of decisions needed to be made, including the best use of

available budget, whether to proceed with the two working boreholes and how to accommodate those

participants who lived in the two villages where the boreholes drilled came up empty.

First, we discussed the process of borehole drilling, the costs involved and how much of the budget

was left thereafter. Some suggestions here included that further sites be surveyed and drilled in the two

villages without water – so that all four should end up with a borehole – and then to find further funding

to develop these boreholes later. It had to be explained to participants that project budgets could not

be so diverted from the purposes for which they were proposed. It was thus decided to continue with

13

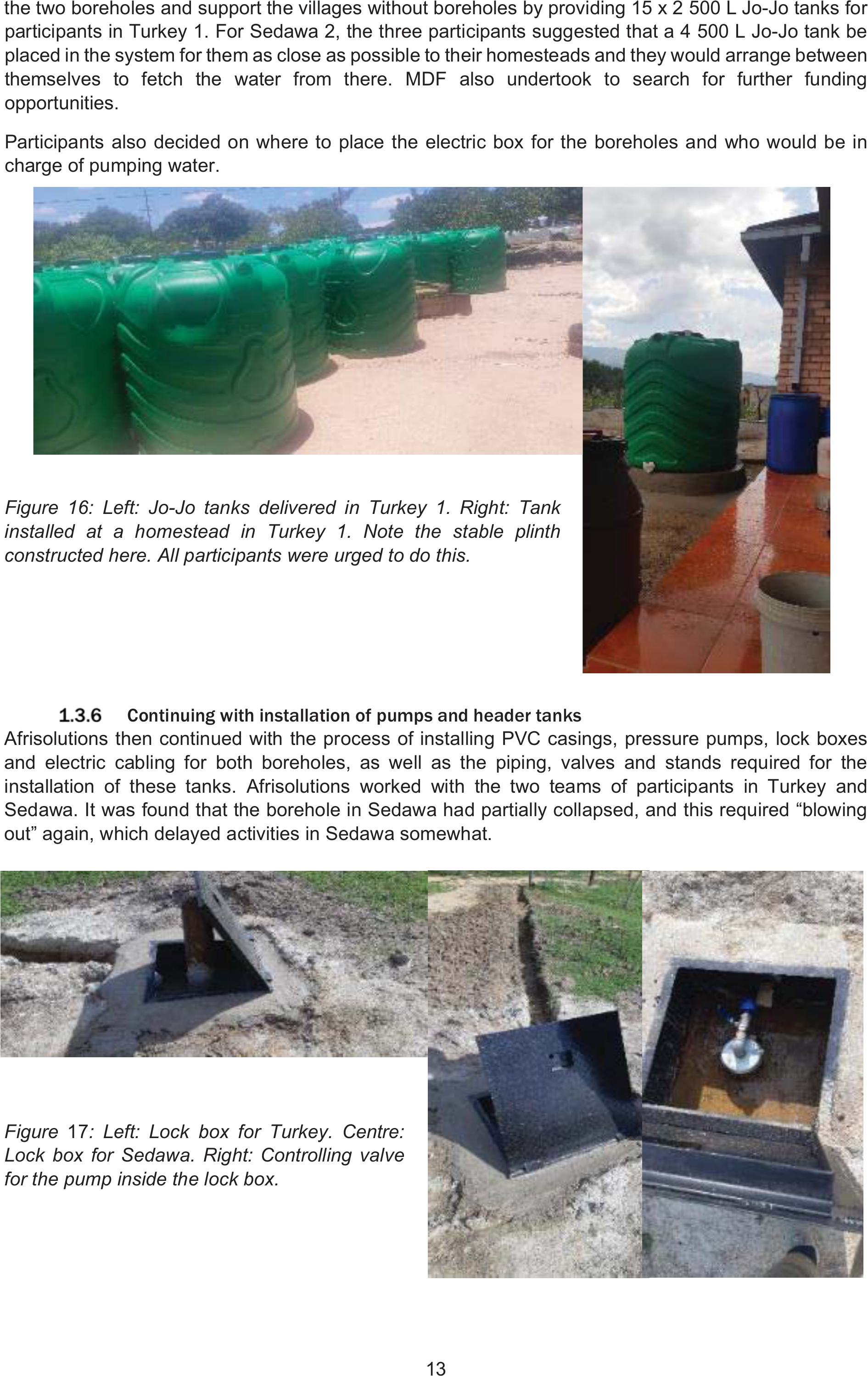

the two boreholes and support the villages without boreholes by providing 15 x 2 500 L Jo-Jo tanks for

participants in Turkey 1. For Sedawa 2, the three participants suggested that a 4 500 L Jo-Jo tank be

placed in the system for them as close as possible to their homesteads and they would arrange between

themselves to fetch the water from there. MDF also undertook to search for further funding

opportunities.

Participants also decided on where to place the electric box for the boreholes and who would be in

charge of pumping water.

Figure16: Left: Jo-Jo tanks delivered in Turkey 1. Right: Tank

installed at a homestead in Turkey 1. Note the stable plinth

constructed here. All participants were urged to do this.

Continuing with installation of pumps and header tanks

Afrisolutions then continued with the process of installing PVC casings, pressure pumps, lock boxes

and electric cabling for both boreholes, as well as the piping, valves and stands required for the

installation of these tanks. Afrisolutions worked with the two teams of participants in Turkey and

Sedawa. It was found that the borehole in Sedawa had partially collapsed, and this required “blowing

out” again, which delayed activities in Sedawa somewhat.

Figure 17: Left: Lock box for Turkey. Centre:

Lock box for Sedawa. Right: Controlling valve

for the pump inside the lock box.

14

Afrisolutions hired three

participants (decided upon in

their groups) to dig the trenches

to take cabling to the households

which would manage the

electricity supply.

Figure18: Left:

Electricity supply in

Sedawa showing the

cable and plug for the

borehole pump. Right:

The cable in Turkey

linked into the electricity box with a switch.

Planning the digging of the main pipeline trenches

The MDF team worked with the two water committees to understand the maps and then undertake

walks to stake out the different sections of pipe, where the pipe sizes changed, which fittings to use and

where the pipes would cross paved roads.

The agricultural engineer also

worked with the committee members

to ensure that they understood how

the fittings worked, what the reducer

couplings looked like and how to

install them. People were confident

that they knew how to do this

themselves.

Figure 19: Erna Kruger and

Alain Marechal working with the Turkey committee to explain the pipeline on their map

The paved road crossings were a cause for concern, but the water committee members felt that they

could easily get permission from their traditional authorities. In Sedawa, the process of approval and

installing pipes below the paving and replacing paving thereafter worked smoothly. In Turkey, however,

local residents stopped work on the day – after approval by the traditional authority – insisting instead

on having a cement speed bump on top of the paving, with the pipes inside the structure encased in a

steel sleeve. They insisted that they did not trust

the water committee or the implementer to restore

the road to its original state after laying the pipe.

Figure 20: David van Wyk from

Afrisolutions working with Alain Marechal

to site and measure the two paved road

crossings in Sedawa

At the same time, Afrisolutions was installing

main tank stands before connecting the Jo-Jo

tanks to the boreholes. Again, some discussion

was required as participants had envisaged much

higher stands and felt that the 1 m high stands

would not allow for proper emptying of their

header tanks. The MDF facilitator and the

engineer needed to re-explain how the heights

15

and pressures were calculated and the reason for choosing these lower and cheaper stands.

Participants took it upon themselves to dig the mainline trenches from the borehole to the header tank

to ensure timely implementation. It was very difficult for participants from Sedawa to cooperate and dig

the trenches. Some participants didn’t work on the trenches, and they all became convinced that the

soil was too hard and rocky to dig. The local facilitator, Christinah Thobejane, requested assistance

from the municipality with digging trenches using a TLB, but was told that the TLB was occupied on a

sanitation project. Participants held meeting after meeting to discuss the way forward. They eventually

reached the decision that they would each dig 20 metres of trench and that each person’s section would

be numbered, so that everyone knew which section they were meant to dig. Most of the participants

adhered to the decisions taken, but there were a few who did not. Participants again made more rules,

where fines of R350 were instituted for noncompliance and the threat that their pipes would not be

connected until they paid the fine.

Figure21:

Left: One of

the Sedawa

group

meetings to

thrash out

how the main

trench would

be dug. Right:

Measuring a

rope to stake

out each person’s 20 m section.

Figure22 (Right): Left: Digging

the main trench to the header

tank in Sedawa. Centre: Alain

Marechal working with Alex and

Magale in Sedawa to stake the

crossings. Right: Digging the

main trench to the header tank in

Turkey.

Once the header tanks arrived in

Turkey and Sedawa and had been

tested, Afrisolutions connected the

pipes.

Figure23: Left: Header tank at Sedawa (Joyce Seotlo). Right: Header tanks (4 500 L each) fully

functional and tested at Turkey (Michael Makgobatlou).

16

Laying the pipes from the header tanks to the homesteads

Delivery of piping was done in both villages and participants started digging their trenches around the

last week of February 2020.

Figure24: Piping and fittings delivered to Sedawa

Figure25: Piping and fittings delivered to Turkey

After the pipes were delivered, participants started laying and connecting the pipes and closing the

trenches with the help of MDF facilitators Betty Maimela and Jessica Mangema. Afrisolutions in the

meantime installed the speed bump across the main road to connect pipes from the borehole to the

main Jo-Jo tank in Turkey.

Figure26: Left:

Sketch for

speed bump

construction

(Alain

Marechal).

Right:

Construction of

speed bump.

After the speed

bump construction,

community members were still unhappy that the bump was too steep and rounded. After much

negotiation, in which the traditional council notably failed to help, Mr Malatji eventually agreed to use

some group funds to buy more cement and the group helped to even out the bump to the grumblers’

satisfaction.

17

At Sedawa, the crossings were done differently – three crossings were constructed on the paved road

sections where the paving was removed, the steel sleeve and pipes were buried and the pavement

carefully replaced. This was completed without incident and the crossings were all but invisible.

Figure27: Left: Final speed bump crossing in Turkey. Right: One of the crossings under the paving in

Sedawa.

Connection of pipes in Turkey

Turkey participants thought it would be a simple job to connect the pipes and that they could do without

the help of the engineer. When they encountered several challenges, however, Betty assisted the

group, with continuous telephonic support from Alain Marechal.

During the process it became clear to the group that if they wanted to divide the participants into two

groups, who received water on alternate days, as they had decided, then further valves would be

required to close off one section and open the other. These were then installed in the lines. It took

participants five days to install all the pipes and fix the speed bump. Below is a figure of one of the

connections and the drawings provided by the agricultural engineer to facilitate the process.

Figure 28: Left; A picture of one of the connections. Centre and Right; drawings indicating how the

connections are put together

Connection of pipes in Sedawa

These participants also thought it would be easy to install their pipes, but found the actual

implementation quite challenging. The figure below shows a photograph and drawings of an example

of the household connector valve for Sedawa.

18

Figure 29: Left and centre; drawings depicting how to install the household connector valve to pipes

and tanks and Right; an example of a household connector valve in Sedawa

The pictures below provide some indication of the work and process in Sedawa.

Figure30: Clockwise from top

left: A homestead connection

into the main pipeline. Top

centre and far right: Digging

out the trenches using picks.

Bottom centre: Laying a pipe

into one of the trenches.

Both these systems and the

system in Turkey are running

smoothly. Participants have calculated the costs and determined the processes for which each

individual is responsible. Generally, pumping is undertaken once a week for each participant, and in

this case, as the borehole is not very strong, participants receive an allocation of 800 L of water per

week.

In Sedawa, participants took longer to install their household connections and tanks and by May 2020

the pumping regime had yet to be finalised. Each participant is to receive 2 200 L of water per week.

In conclusion, these processes have been a very important empowerment process for these villagers,

who now have access to a reliable, self-managed source of household water.