Poultry Monitoring–Matatiele June 2015

Introduction and summary

The KZNPI participants alongside attendees of Isiqalo trainings were visited in order to see how the

farmers were implementing the concepts they had learnt during the courseand learning sessions.

Of thepoultryfarmers interviewed, 89%were female. Forty onepercent of the farmers are part of SCG’s.

Seventy sixpercent of the farmers receive social grants(of which 90% are child grants), making them more

dependent on theirpoultry enterprises as a source of income. The average monthly income the farmers

receive is R2206. This makes it challenging for farmers to invest money into their enterprises to improve it

and/or expand. It becomes more of a challenge if the farmer has many dependants. Ninety fourpercent of

the poultry farmers visited have a broiler flock, while 47% of the farmers have a multipurpose flock. All of

the farmers use maize crush on their broiler flocks while 76% of the farmers use broiler feed (starter and

finisher) on their broilers. The frequent use of maize crush is attributed to the affordability of maize crush.

The farmers use maizecrush during the latter stages of the production cycle, mostly when they have ran

out of broiler feed.

Sixty five percentof the farmers are in a bulk-buying group (birds purchased via SaveAct) while the rest

bought at street vendors and suppliers in town, local informal, EggVet and family farms. A culture of record

keeping needs to be fostered and instilled in farmers sinceonly 41% keep records. In other words, more

than half of the poultry farmers do not know whether they made a profit or not, let alone how much.

A segment of weighing birds was included during the monitoring process. This was to create a snapshot of

the average weight of the birds. Weighing the flock plays an integral part of record keeping and monitoring

the enterprise. However, only one of the farmers has a weighing scale (Tumelo Sauli). All birds weighed

were mature and market-ready (over 42 days).The current average weight for broilers is 3.1kg while the

average for the multipurpose birds is 3.3kg. However, the birds (both broilers and multipurpose) of the

respective farmers were not the same age. The broiler farmers were feeding their mature birds

133g/birds/day on average. The broiler farmers have sold 26% of their stock to date and have consumed

an average of 3 per batch.

Forty fivepercent of the farmers said they experienced challenges related to diseases and 35% said their

challenges were market related. The farmers visited, on average, bought 32birds when stocking. It would

be beneficial for the farmers if their respective bird numbers increased; more profits will be made through

low input costs per bird.

The brooding period for the farmers is 2-3 weeks;this is an indicator thatthe farmers are using knowledge

acquired during the course and learning sessions. The average mortality of their enterprises is 17%, this

can be lower for KZNPI participants for the next cycle because then will they be able to use most of their

new poultry expertise. Eighty sevenpercent of the farmers visited use kraal manure (5.5cm on average) in

their chicken houses. This is mostly because in contrast to buying sawdust/shavings, the kraal manure is

easily accessible and in most cases, free.Only 7% were using dry grass as floor shavings.Fiftytwo

percent of the farmers have a lighting programme, which is a vital attributor of feed intake.

Twenty sixpercent of the farmers had stock left over from the previous cycle, around 12kg of maize crush

on average. Ninety threepercent of the farmers sell their birds live to neighbours (with one farmer

considering sending to an abattoir)at an average price of R93/bird. One farmer, Mrs. Zingiswa Mbadu,has

incorporated value-adding into her enterprise. She sells live to neighbours at R100, R85 for school 1which

purchasesslaughtered birdsand R100 for school 2which orders chicken pieces. Farmers with the multi-

purpose flock had an average of 13 birds which were sold at anaverage price of R95/bird.

Figure 1. Left: feeder made by Tumelo Sauli. Right: Mr. Sauli’s drinkers and lamps

Figure 2. Left: Thabiso Diholo’s broilers. Right: Mr. Diholo’s multi-purpose hen.

Figure 3. Left: Nozipho Mthimkhulu’s advertisement. Right: Mrs. Mthimkhulu’s flock.

Figure 4. Left: Pulani Minyelela’s chicken house. Right: Weighing of Mrs. Minyelela’s birds.

Figure 5. Thandazile Nondabula’s paraffin lamp. Right: Nonkosinathi Magobola’s multipurpose birds

Summary of information for 25 poultry producers interviewed.

Poultry activities

N=25

Sex

89% Female, 11% Male

Are you in a SCG?

41% Yes, 59% No

Does HH receive social grants?

No grant = 24%, With grant = 76%(90% Child

grant, 10% Pension)

Average monthly income

R2206

Main source of income for HH

11% Remittances,37% Employment, 45% Social

grants, 7% Own Enterprise

Do you have a broiler flock?

94%

Do you have a layer flock?

6%

Do you have a multipurpose/indigenous

flock?

47%

Do you use broiler/layer feed?

76%

Do you use maize crush?

94%

Are you in a bulk-buying group?

65%

Your source of feed

59% SaveAct

41% Vendors in town, suppliers in town, local

informal, EggVet and family farms

Feed provision (g/bird/day)

133g/day/bird

Current average weight -broilers

3.1kg

Do you keep records?

41%

Source of drinking water?

71% Municipality

18% Rainwater

11% communal tank

Challenges experienced with the

enterprise

45% Diseases

35% Market related

20% Other

Initial number of birds (purchased)

32

Days of brooding

2 –3 weeks

Mortality

17%

Type and depth of floor shavings

87% use kraal manure, around 5.5cm. 7% use dry

grass

Lighting programme

52% have a lighting programme

Stock left over at end of cycle

22% had stock left over.

How do you market your birds?

93% sell live birds locally

7% sell to local schools

Price per bird-Broilers

R98

No. of bird sold

26% stock sold

No. of birds consumed in the cycle

3

No. of birds -Multipurpose

13

Current average weight -Multipurpose

3.3kg

Average price per bird -Multipurpose

R95

Case studies for a slected number of poultry producers

Poultry Case Study; Mrs. Nolulamile Mazitshana. Lubisini (May 2015)

Nolulamile Mazitshana, is a 52 woman determined to improve her household livelihood status and

encourage others to do so through broiler production. She lives in Lubisini, a remote village located in the

outskirts of Matatiele. Alongside her budding broiler enterprise is her vegetable garden which she uses for

household consumption. Initially, she ventured into broiler production with the aim of consumption

smoothing. This was a decision she made when she realised the amount of frozen chicken she purchases

per month and the money spent thereof was a considerable part of household expenses. The idea of

growing broilers surfaced. She started with 10 –20 birds per cycle.

At a later stage, she realised that many of community members in her village are facing the same

predicament she was in. There are not many broiler producers in the vicinity of the Lubisini village, those

that do produce, produce predominately for household consumption. As a result of her eureka moment, she

began producing broilers to sell. She sells her birds live to community members at R40 per bird. She

explained that her market is resolute for most parts of the year. When people buy her birds, they seldom

purchase less than 5 at a time. Some customers buy from Mazitshana to continue rearing the birds until

they are ready to slaughter them. “People travel from Ghobho (a village neighbouring Lubisini) to buy my

chickens” she explained as she gestured her pride, and rightfully so.

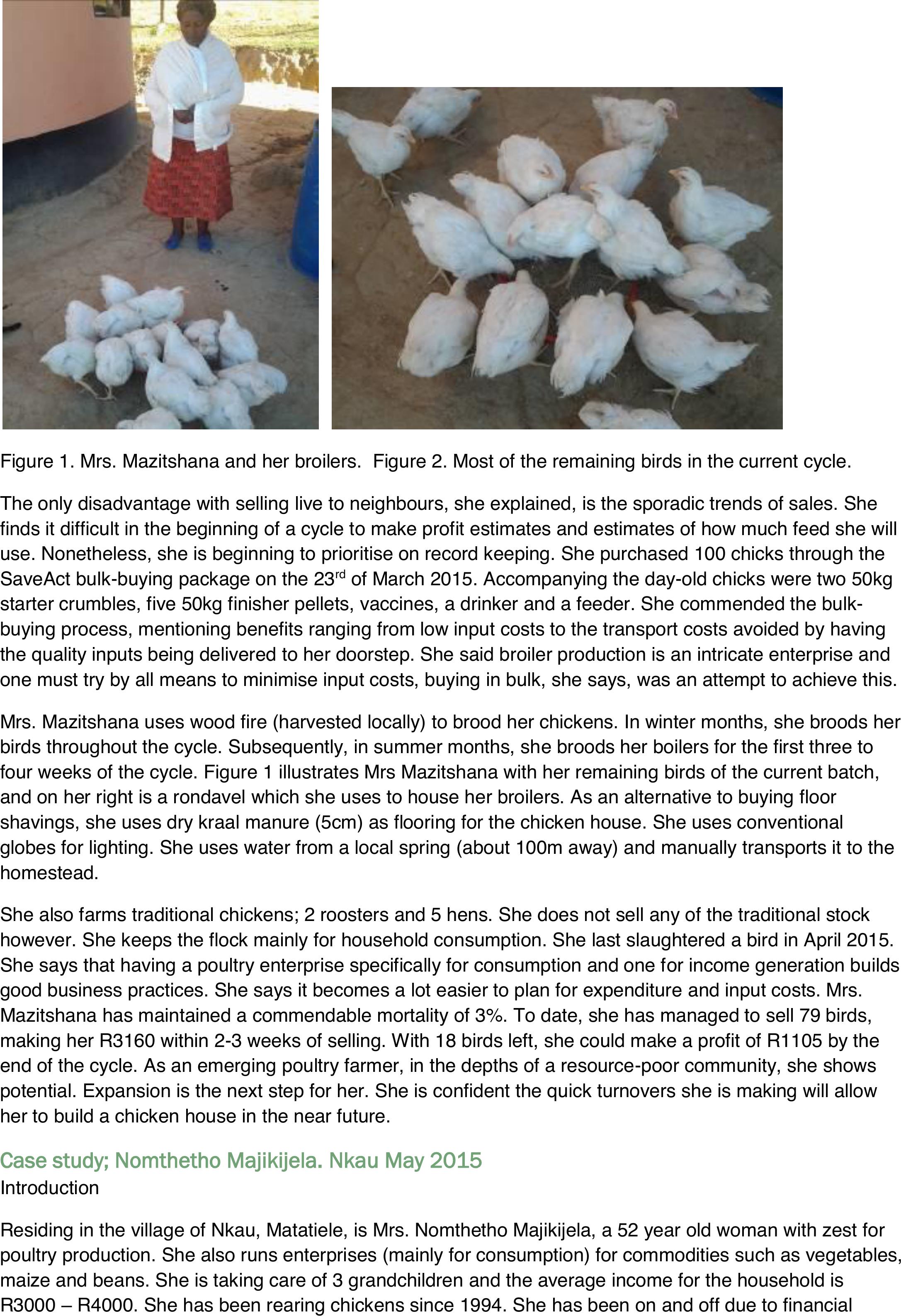

Figure 1. Mrs. Mazitshana and her broilers. Figure 2. Most of the remaining birds in the current cycle.

The only disadvantage with selling live to neighbours, she explained, is the sporadic trends of sales. She

finds it difficult in the beginning of a cycle to make profit estimates and estimates of how much feed she will

use. Nonetheless, she is beginning toprioritise on record keeping. She purchased 100 chicks through the

SaveAct bulk-buying package on the 23rd of March 2015. Accompanying the day-old chicks were two 50kg

starter crumbles, five 50kg finisher pellets, vaccines, a drinker and a feeder. She commended the bulk-

buying process, mentioning benefits ranging from low input costs to the transport costs avoided by having

the quality inputs being delivered to her doorstep. She said broiler production is an intricate enterprise and

one must try by all means to minimise input costs, buying in bulk, she says, was an attempt to achieve this.

Mrs. Mazitshana uses wood fire (harvested locally) to brood her chickens. In winter months, she broods her

birds throughout the cycle. Subsequently, in summer months, she broods her boilers for the first three to

four weeks of the cycle. Figure 1 illustrates Mrs Mazitshana with her remaining birds of the current batch,

and on her right is a rondavel which she uses to house her broilers. As an alternative to buying floor

shavings, she uses dry kraal manure (5cm) as flooring for the chicken house. She uses conventional

globes for lighting. She uses water from a local spring (about 100m away) and manually transports it to the

homestead.

She also farms traditional chickens; 2 roosters and 5 hens. She does not sell any of the traditional stock

however. She keeps the flock mainly for household consumption. She last slaughtered a bird in April 2015.

She says that having a poultry enterprise specifically for consumption and one for income generation builds

good business practices. She says it becomes a lot easier to plan for expenditure and input costs. Mrs.

Mazitshana has maintained a commendable mortality of 3%. To date, she has managed to sell 79 birds,

making her R3160 within 2-3 weeks of selling. With 18 birds left, she could make a profit of R1105 by the

end of the cycle. As an emerging poultry farmer, in the depths of a resource-poor community, she shows

potential. Expansion is the next step for her. She is confident the quick turnovers she is making will allow

her to build a chicken house in the near future.

Case study; Nomthetho Majikijela. NkauMay 2015

Introduction

Residing in the village of Nkau, Matatiele, is Mrs. Nomthetho Majikijela, a 52 year old woman with zest for

poultry production. She also runs enterprises (mainly for consumption) for commodities such as vegetables,

maize and beans. She is taking care of 3 grandchildren and the average income for the household is

R3000 –R4000. She has been rearing chickens since1994. She has been on and off due to financial

stressors. She has been farming traditional chickens for over 20 years and began broiler production about

4 years ago.

Mrs. Majikijela is a member of Noncedo, a Saving and Credit Group which she says played an integral part

in helping her run and expand her poultry enterprises. She bought 30 broilers in the current cycle and is

planning on moving to 50 per cycle. In retrospect, she had been buying from informal chick sources,

unaware of its repercussions. She plans on buying from reliable sources and to continuously seek expert

advice.

She had a high mortality with her broilers in the beginning and realised broiler production is a lot more

complex than rearing a traditional flock. Her experience in broiler production has gradually improved her

expertise. She says that her experience, coupled with her passion for poultry production, she is bound for

success. In recent months, record keeping has taken precedence over other activities in her poultry

enterprises. She said she realised it is the most important way she can monitor the feasibility of her

enterprises.

She normally uses dry grass, kraal manure or a combination of both for her flooring in her broiler house.

She uses a lighting program which calls for keeping lights on for 24hrs for the first 2 weeks. She then after

starts steadily decreasing the light hours by two hours a week. By week 6, the birds get 16hrs of light. In an

attempt to minimise input costs, she cuts car tyres in half and uses them as feeders. She uses a paraffin

stove for brooding her chicks, which is a two week period. She uses her paraffin stove as a brooder and

purchases paraffin locally which costs her R65 / 4litre. During the winter months, she continues her

brooding system but decreases the temperature after two weeks. She sells her broilers at R130/bird. She

says her customers are comfortable with her pricing because her birds are heftier than other broiler

producers’ in the area. Her average weight of her broilers is 3.8kg. For the current cycle, there has been a

mortality of 5 birds and she has sold 10 birds to date. If she is to sell all the remaining birds (with no added

expenses), she will make an income of R3250, and a profit of R2150.

Figure 1. Chicken house where she keeps her chicks for 2 weeks (left). Figure 2. Chicken house for birds

2+ weeks.

Figure 1 depicts a newly built chicken house she uses for her broilers at day old to 2 weeks. She built the

small house solely for her broiler enterprise. She then moves her two week old birds into the second broiler

house shown in figure 2. She mentioned that she will purchase the second batch of broilers when there are

a few birds left of batch she is currently selling. This is to ensure the bigger chicken house is ready to

accommodate the 2 week olds. Mrs Maijikela described her production regime which mainly targets 3

market opportunities; the festive season, Easter holidays and June/September school holidays. However,

she explained that years may vary depending on her situation, financial and otherwise.

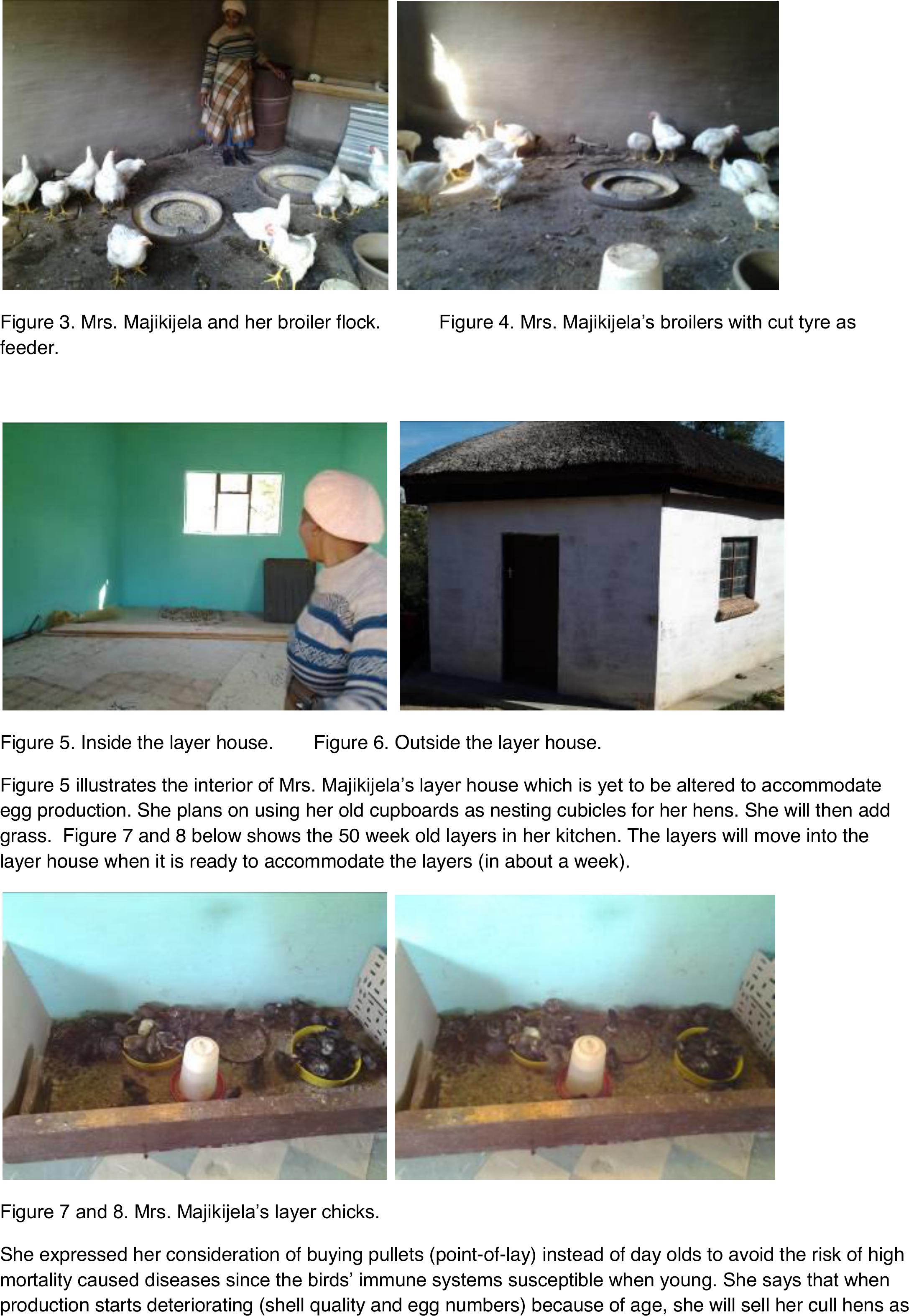

Figure 3. Mrs. Majikijela and her broiler flock. Figure 4. Mrs. Majikijela’s broilers with cut tyre as

feeder.

Figure 5. Inside the layer house.Figure 6. Outside the layer house.

Figure 5 illustrates the interior of Mrs. Majikijela’s layer house which is yet to be altered to accommodate

egg production. She plans on using her old cupboards as nesting cubicles for her hens. She will then add

grass. Figure 7 and 8 below shows the 50 week old layers in her kitchen. The layers will move into the

layer house when it is ready to accommodate the layers (in about a week).

Figure 7 and 8. Mrs. Majikijela’s layer chicks.

She expressed her consideration of buying pullets (point-of-lay) instead of day olds to avoid therisk of high

mortality caused diseases since the birds’ immune systems susceptible when young. She says that when

production starts deteriorating (shell quality and egg numbers) because of age, she will sell her cull hens as

Cornish hens for around R30/bird. She purchased the layers with idea of targeting the local market of eggs

and that of Cornish hens (since they do appear as traditional hens and are catchy on the local’s eye).

She will be selling her eggs at R1,50 each. With 50 birds, she could be making an income of around R420

a week, given she has a low mortality and she uses the correct layer production practices (40 birds laying

an egg a day). This however will depend on how her local market responds.

Poultry Case Study; Zingiswa Mbadu. Jabulani May 2015

Fourty-five year old Zingiswa Mbadu is an active entrepreneur and community member of Jabulani (a

village situated about 20km outside Matatiele). She is a wife and a mother of one. Mrs. Mbadu’s husband

works in Johannesburg. She receives a government child grant and the monthly income for her household

in R3000-R4000. She farms broilers and a traditional flock. In 2013, she was faced with the misfortune of

losing her homestead to an accidental fire. Fortunately, no one was injured during the process. Along with

her valuables was a flock of 800 birds which perished in the fire. In the past year, Mrs. Mbadu has been

trying to source funding from the department of Agriculture to improve and expand her broiler enterprise.

“Just a little start-up capital to get the ball rolling”, she adds. However, her efforts are yet to come to avail.

She feeds her birds starter crumbles and finisher pellets. A week before marketing the birds (at 5 weeks)

she changes her feed to feeding maize crush. She maintains that the maize crush gives the meat a taste of

grain fed birds. She reiterated that she is aware that maize slows down muscle/meat production, but she is

trying to listen to her customers. She says that she could not and cannot dispute with the preferences of

her customers.

Figure 1. Mrs Zingiswa Mbadu

At one point, Mrs. Mbadu was producing 1000 broilers of varied ages concurrently. She was buying 200

hundred day-olds at a time to meet her market demands. The vibrant Mrs. Zingiswa Mbadu has been

growing broilers for over a decade. She began small and started expanding as she realised her enterprise

was not brisk enough when it came to turnovers. “Broilers are a numbers game”, she said,” the more birds

you have, you have a better chance of generating higher profits”.

She was producing for neighbours and four schools, in her village and neighbouring village. She had two

schools which were secure markets. One school purchased slaughtered chickens at R85/bird and the other

school purchased chicken piecesat R100/bird. For neighbours, she sold live broilers but was able to

slaughter and cut pieces on request. Mrs. Mbadu’s customers (community members) paid R10 more than

the schools did for the value-added chickens. This was because the schools were buying in larger

quantities, thus were given discounts. At the peak of Mrs. Mbadu’s broiler enterprise, she was selling

around 200 birds every fortnight. Her average bird weight for her last batch was 2,8kg. She also sells her

traditional flock at R150 per bird. She explained that her traditional flock targets a market of people who

look for colours of feathers in birds, for custom occasions or just for breeding.

After losing almost all her possessions to the fire, she acquired land about 100m away from where her

house was. She began building a new homestead on the new site. Undeterred by the aftermath of the fire,

she started farming broilers again. Her last order was 100 day-old chicks from EggVet (in Matatiele). She

had an impressive mortality of 4% in her last cycle and sold 96 birds. She made a profit of R4280 for her

batch. A crucial element which makes her enterprise rise above others is that she tries to move down the

value-chain (closer to the consumer) through value-adding. Taking advantage of this opportunity cost has

evidently worked in her favour.

In November 2014, she was given an opportunity and agreed to undergo poultry production training at the

KwaZulu-Natal Poultry Institute in Pietermaritzburg. She explained how the week long training has

improved her knowledge in poultry production. “It was an eye-opener”, she explained, “I could see myself

owning one of the farms being exhibited during the KZNPI seminars.” Oozing with energy, she recalled her

experiences from theoretical learning to practical experiences. She is also happy the training course gave

her something tangible. She plans on using the KZNPI certificate to better her changes of acquiring

funding.